New milling technology, that advances the traditional milling capability, has recently been announced. It comes courtesy of a new advancement from Vero UK in their Edgecam software range, and has been christened “Waveform Roughing Strategy”.

The New Milling Technology Deserves a few Plaudits

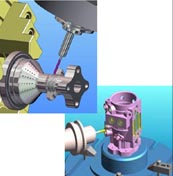

It’s a rare event when something new comes along in the engineering world, so this new milling technology deserves a few plaudits. Edgecam software is cutting edge stuff, if you’ll excuse the play on words. These software programs are specifically targeted at the high precision machining sector within the engineering industry. It’s state of the art CAM/CAD application which takes advanced tool-path engineering and seamlessly melds it with CAD output. The growing library of Edgecam software packages is intent on improving productivity through the manufacturing cycle.

Waveform Roughing Strategy Signal New Milling Technology Advancement

Waveform roughing strategy has been formulated in order to increase material removal rates while the machining process is in operation. By evacuating off-cuts and swarf as the blades and bits are cutting, it enables them to cut faster by minimising resistance to the cutting implements. As well as increasing the actual cutting speed, it also contributes significantly to extending the working life of both cutter and machine. In addition, the new waveform roughing strategy also gives the new milling technology the ability to cut greater depths.

Working Details of the New Milling Technology

The new Edgecam milling software actually creates a rougher mill path. This helps to improve process cycle times, as well as facilitating a better surface finish. By enabling the distance between the roughing passes to vary, this produces a more uniform width of cut which results in any spikes being removed. It means that the chip load remains constant, and that the cutter itself can cut to the full length of its flute.

Embracing the New Milling Technology – Oh Ye of Little Faith

Introducing new technology to an engineering machining workforce can be challenging. Things like cutting speeds and depth of cut are ingrained in training and experience. But Edgecam’s new milling technology does recommend working outside of existing parameters in order to maximise results. So it takes something of a new measure of trust to fly in the face of old recognised procedure. However, you’ll find that the proof of the pudding is in the eating, as they say. Once operatives have tried it out for themselves, they’ll have to rewrite their training notes when they’re using waveform roughing strategy.

Taking Advantage of the New Milling Technology

“Faint heart ne’er won fair maiden”, so the saying goes. In other words you sometimes have to make bold decisions if you want to stay ahead of the game. The high precision engineering machining industry is a very competitive sector to work within. Anything that can give companies an edge can make all the difference, especially when it delivers improved procedures and quality. The signs are it’s only going to be a matter of time before more and more engineering machining companies begin taking up this new milling technology.

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Mail:

Mail:

Leave a Comments