Engineering Challenges are PRV Engineering’s Bread and Butter

Engineering challenges come in all sorts of shapes and sizes. For the ordinary man and woman on the street, engineering may not be the most exciting topic for many ordinary everyday folk, but when it takes place within an environment such as space exploration, it takes on a whole new persona.

Space – Engineering’s Final Frontier

Designing and engineering precision parts for space vehicles is an awesome responsibility. It’s quite disturbing to think that one tiny flaw in design and/or manufacture could scuttle a mission. It could result in the obliteration of millions of pounds worth of satellite hardware, and the ruination of the anticipation, the hopes and the dreams of millions of people.

Bread and Butter for PRV Engineering

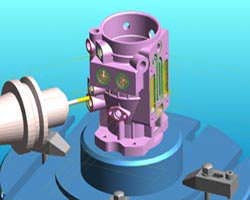

Engineering challenges don’t get any tougher than this. But it’s exactly the sort of work that is bread and butter to an engineering machining company like PRV Engineering. Whether they’re working for the aerospace industry or the rail industry, they still set themselves the highest standards and the tightest tolerances to work within.

A Triumph of Engineering

News of the successful landing on Mars made by “Curiosity” was announced earlier this month. It followed a marathon eight and a half month journey through outer space at the end of which the spacecraft set down exactly where it had been planned, and right bang on time too! It was a triumph, not only for the physical precision engineering that had gone into the project, but for the specially engineered software too.

One of the Toughest Engineering Challenges

But the voyage through space and the soft landing on the Red Planet’s surface were only preparation for the main event – a new bout of exploration of the surface of Mars. More super precision engineering and specialised software were called upon in the building of the SUV sized Rover that is specially designed to carry out this mission; one of the toughest engineering challenges ever.

Thunderbirds are Go!

Curiosity’s Rover weighs in a little over 900 Kg and was designed to be released from the module in the final moments of descent. It was then lowered via a special rocket powered sky-crane down onto the planet’s surface. Thunderbirds come to life!

Doing it Outside the Box

But thinking outside of the box is what is called for when you’ve got to deliver something special. It’s what engineering challenges are all about. PRV Engineering know this only too well and always seek innovative solutions whether it’s in the manufacture, the assembly or the installation of a special piece of kit going into a difficult and demanding environment.

Mind Boggling Engineering

The Rover has to perform its pre-programmed routines without human supervision, so reliability is a perquisite that was built into its design. If the harshness of Mars’ surface in itself is not enough of a challenge, Curiosity has to whether enormous swings of temperature, from -135 °C to +50°C. The engineering challenges posed by that were also quite boggling.

One of the Best Engineering Problem Solvers on the Planet?

In situations like these, where the failure of component simply isn’t an option, there’s no such thing as over-engineering. PRV Engineering are all too familiar with the concept. But unlike the space industry, where money is no object, they have to achieve fitness for purpose within tight cost constraints too. It’s what makes them one of the best engineering challenges solvers on the planet – Planet Earth that is.

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Mail:

Mail:

Leave a Comments