3D Modelling and Computerised Simulation Software Plunge to the Deepest Depths

3D modelling and computerised simulation are still relatively new concepts in the engineering world. Their arrival has enabled the modelling and prototyping of components that have amazingly complex profiles. But in the greater scheme of things, they have also played a fundamental part in enabling man to land at the deepest place on Earth – the bottom of the Mariana Trench, the ravine that scores the sea bed of the western Pacific Ocean, stretching for some 1,500 miles off the coasts of Japan and China.

First Man at the Earth’s Nadir

Movie blockbuster director James Cameron made the historic dive last year, the first man ever to have made the dive to the deepest reaches on the planet. He seems to have an obsession with our oceans. In 1989 he directed “The Abyss”, the movie that revealed an alien civilisation living in the Cayman Trough, the deepest point of the Caribbean Ocean. Then in 1997 he directed movie blockbuster “Titanic”. The move in which Kate Winslet and Leonardo Dicaprio starred, dramatising the sinking of the White Line liner on its maiden voyage across the Atlantic from Southampton to New York in 1912. In 2005 Cameron part directed “Aliens of the Deep”, a documentary which explored the life-forms that dwelt around hydrothermal vents in the Atlantic and Pacific oceans.

The Unsung Heroes of Engineering used 3D Modelling and Computerised Simulation

Whilst Mr Cameron may have stolen the limelight for mans’ deepest ever dive, it’s undoubtedly the engineering skills and innovations that turned the journey from an ambition into a reality. With no actual experience of the extreme conditions that are found 7 miles below the surface of the sea, it was down to 3D modelling and computerised simulation to test what a vessel travelling to these depths would encounter. Intense cold, total darkness, and pressures of 16,000 pounds per square inch, are just some of the factors that were part of the simulation.

Inner Space v Outer Space

Cameron likened the journey to a trip into outer space. He described the sea bed, illuminated by the strong searchlights of the vessel “Deepsea Challenger”, as Lunar in its appearance. Harking back to his other obsession with aliens, (The Abyss, Aliens of the Deep, and Avatar), he described the life-forms in this most inhospitable of environments as, “from another planet”. All were white bodied, as colour is somewhat irrelevant in total darkness. But some creatures had “eyes” through which they could see the bio-luminescence that other creatures emitted.

3D Modelling and Computerised Simulation Replaces Guesswork

Philip Durbin, one of the engineers involved in the design and construction of Deepsea Challenger revealed that all aspects of the vessel were realised through 3D modelling and computerised simultaion techniques. The 24ft vessel, (only 43 inches wide), was likened to a vertical torpedo. Torpedo like fins were added when the 3D modelling and computerised simulation readouts suggested that currents and buffeting during Challenger’s “flight” back to the ocean surface would be severe. Also the fact that the vessel would shrink by 3 inches due to the extreme pressure had to be dealt with too.

Durbin went on to say that before 3D modelling and computerised simuation became a commercial reality, these sorts of factors, and their effects, could only be estimated.

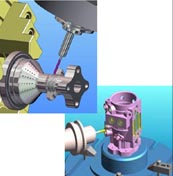

PRV Engineering use Computerised Simulation Software in the Construction Industry

3D modelling and computerised simulation is now used by many top engineering companies like PRV Engineering to facilitate high speed prototyping. They also use it to provide their clients within the construction industry with stress factor analysis. It may not be quite as glamorous as diving to the deepest parts of the planet, but it’s a practical interpretation, courtesy of 3D modelling and computerised simulation, that helps to ensure structures are safe and fit for purpose.

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Mail:

Mail:

Leave a Comments