Decarbonising The Aviation Sector: Electric vs Hydrogen Aircraft

We harnessed the power of flight more than a century ago when Wilbur and Orville Wright achieved the first powered, sustained and controlled aeroplane flight. Over time, this technology advanced allowing people to connect from all over the world fast than ever. However, this form of transport relies entirely on fossil fuels and that’s not a sustainable, long-term solution. If we are to succeed in decarbonising the aviation sector, we need another plan but will it be electric planes or hydrogen aircraft?

Fossil Fuels And The Aviation Sector

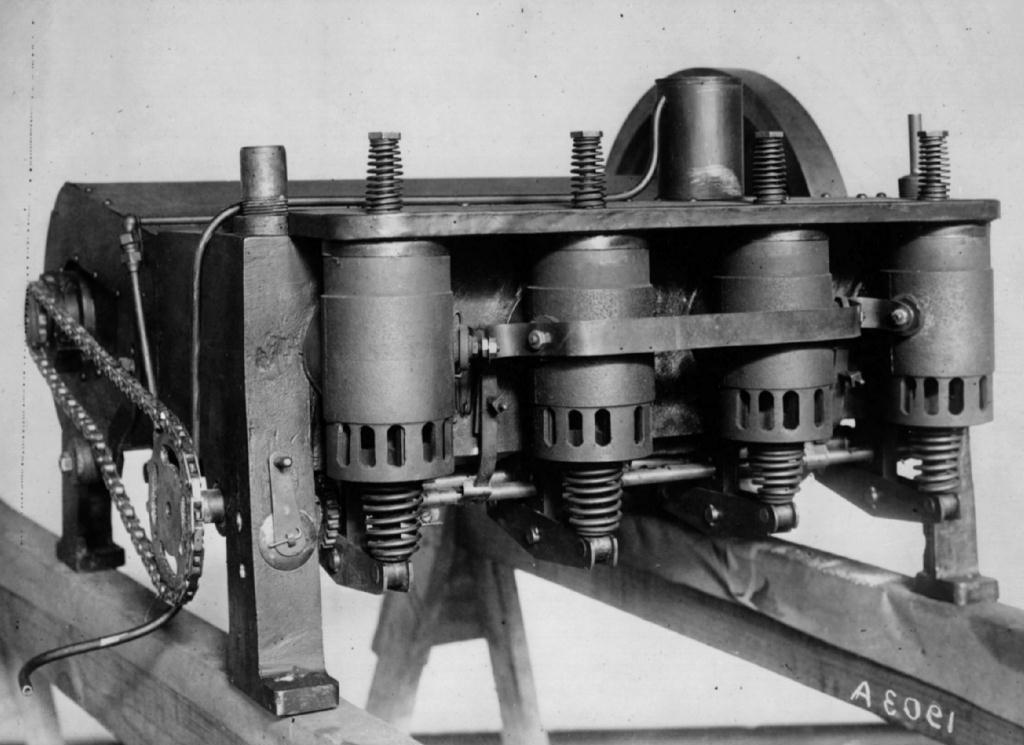

Looking back at the history of powered flight, fossil fuels have always been used to achieve the desired thrust. Even the 1903 Wright engine used gas as fossil fuels are relatively easy to harvest and have loads of usable energy which is called “specific energy”. It measures how much energy each unit mass of fuel contains and is one of the primary reasons the aviation industry continues to use fossil fuels.

So, now that we’ve established why the sector relies so heavily on fossil fuels, could electric planes or hydrogen aircraft supersede fossil fuels? Considering the continued improvements in the automotive sector, what will it take to get the aviation industry to that stage? It all starts with understanding aircraft design, the different fuel types and densities.

Fuel Density And The Energy-Weight Balance

It’s not easy getting (and keeping) an aircraft in the sky as it involves a lot of math and engineering. Aircraft must be light enough to fly while being strong enough to safely perform the desired functions such as transporting people or goods. Before you can create a new fuel system, you must know how heavy the craft will be, how far you plan on going and how fast.

Once you know those values, you can start adding a fuel source whether it’s jet fuel, batteries or hydrogen. Each system will require different mechanical components which have different weights over and above the mass of the fuel. Without stating the obvious, the more fuel you add, the heavier the craft will be and that means using more fuel. So, the secret is finding the right balance but what does that entail?

‘Specific Energy’ Of Hydrogen Aircraft, Electric Planes And Jet Fuel

To get a typical 737-sized plane to travel up to 600 nautical miles (1111.2 km), you need a fuel that can generate about 800 watt-hours of energy per kilogram (Wh/kg). This energy-weight balance could accommodate approximately 50% of all flights across the world. In comparison, jet fuel has a specific energy of around 12,000 Wh/kg whilst hydrogen is about 39,500 Wh/kg which is three times more efficient than jet fuel.

Indeed, hydrogen has the highest specific energy for any practical fuel as the only other fuels with higher energy to mass ratio are radioactive. On the lower end of the scale are lithium-ion batteries as the best ones available today have a specific energy of 250 Wh/kg. That is quite low in comparison to hydrogen and fossil fuels but they are getting better.

The Promise Of Hydrogen Aircraft

Hydrogen could be the best-ever fuel for internal combustion engines as it’s colourless, odourless, non-toxic, and clean-burning energy. It’s also abundantly available, although bonded in chemicals like water and methane. Some experts have said that many of hydrogen’s properties also make it safer to use than fossil fuels.

As good as hydrogen is, we are limited by the current infrastructure capacity and how we build aircraft. Considering liquid hydrogen only has a quarter of the energy by volume as jet fuel, you would need a plane with fuel storage tanks four times bigger than. A common way manufacturers create more storage space is by sacrificing the total number of seats or increasing the size of the airframe.

Hydrogen Mining Methods

Hydrogen production can be a complex process and there are various methods available. The United States use steam-methane reforming which is a widely adopted method, accounting for 95% of all hydrogen produced.

It relies on natural gas and works by mixing hydrocarbons with water which then produces carbon monoxide and hydrogen as a by-product. Unfortunately, this hydrogen mining method is not carbon-free and doing this will only shift aviation’s carbon pollution elsewhere.

Thankfully, there is another process called electrolysis that allows the production of hydrogen from renewable sources using only water and electricity. Electrolyzers need to get electricity from a renewable source like solar energy to sustainably produce hydrogen. When hydrogen is produced using a carbon-free method, a hydrogen aircraft would only release water and heat as a by-product.

What About Electric Planes?

Achievements in electric aeroplanes have made headlines in recent years with many great projects already underway. Today, most electric planes on the market are small, like one to four-seaters that can fly from 15 minutes to around two hours with a maximum range of 300 miles (483 km).

Lithium-ion battery technology is over 30 years old and naturally, there are some concerns over adapting it in the age of electronics. These batteries are susceptible to overheating which can result in dangerous, long-burning fires. Not to mention mining the required rare metals has a significant financial and environmental impact.

Next-Generation Battery Technology

In theory, lithium-ion-powered planes are well-suited for regional flights carrying 30-200 passengers and within 310 miles or 500 km. Many energy experts believe this is the upper limit of lithium-ion batteries but a new type of battery could change that perception as all eyes are currently on lithium-sulfur batteries.

Lithium-sulfur technology could potentially offer cheaper and lighter batteries with a higher safety rating. It could have a theoretical energy density of around 2,700 Wh/kg which is a big step in the right direction but we are not there yet. The existing batteries are already achieving specific energy of 100-265 Wh/kg whilst Oxis Energy claims they have developed a lithium-sulfur battery that with a specific energy of 450 Wh/kg, and there are plans to reach 600 Wh/kg by 2025.

Examples Of Hydrogen Aircraft, Electric Planes And eVTOL Vehicles

Companies like ZeroAvia have already started designing externally-mounted storage tanks for smaller planes carrying 20 people within 500 miles or less. Airbus has also revealed three concept aircraft of different sizes that could enter commercial service by 2030.

Going electric is also creating more opportunities for electric vertical take-off and landing (eVTOL) vehicles. Some examples include MIT’s concept of a Hybrid-Electric Plane, Solar Impulse II, the Rolls-Royce Accel1 and Jaunt ROSA eVTOL among many others.

Conclusion

The future of hydrogen aircraft and electric planes face a similar issue that can only be solved by technological advancements. Fuel systems made from hydrogen fuel cells and lithium-ion batteries are often big and extremely heavy, especially when scaling the system to power larger passenger aeroplanes travelling more than 1000 mi (1600 km).

Due to the aforementioned lack of infrastructure for sustainably producing hydrogen, it’s currently very expensive to manufacture. Companies have been producing hydrogen at scale for various industrial functions for some time so it can be done but now it has to become carbon-free way and more affordable.

PRV Engineering works closely with several industries including aerospace, defence, construction and rail among others. For more information about our products and services, visit the website or read our blog for more interesting articles.

Mail:

Mail:

[…] Recommended: Which Way Forward – Electric or Hydrogen Aircraft? […]