Mould tooling is a vital aspect of plastic manufacturing, and while the initial cost of producing the tool can be substantial, the economies of scale make it worth the investment. However, it’s still essential to avoid unnecessary expenses during the design for manufacturing (DFM) process. In this article, we take a closer look at some of PRV Engineering’s top tips for saving money on mould tooling.

What Is Mould Tooling?

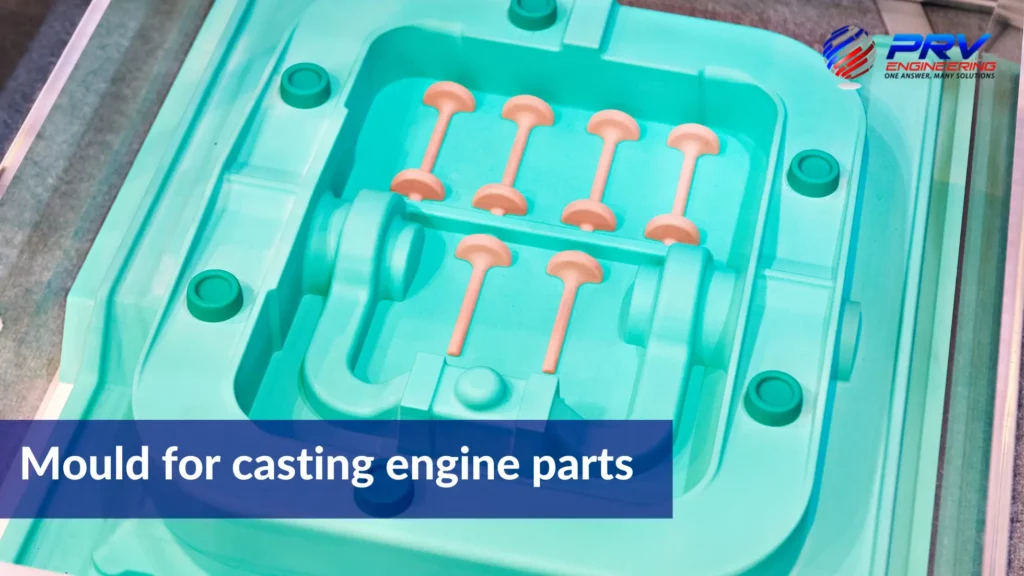

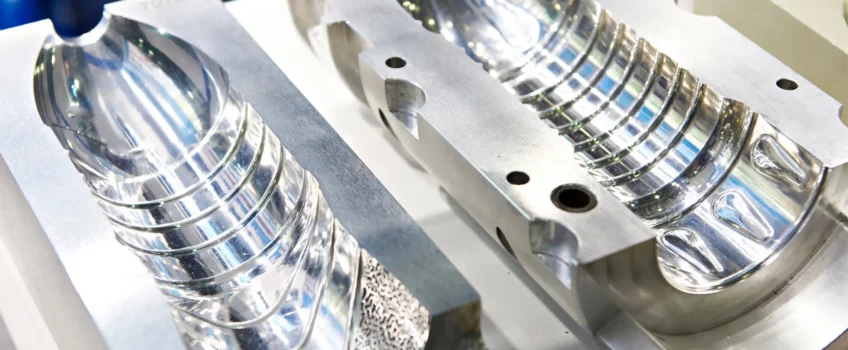

Mould tooling is the process of creating tools or moulds that are used to manufacture plastic or metal parts. These moulds are typically made from high-strength materials such as steel, aluminium or composites and are designed to be precise and durable.

The mould tooling process involves several steps, including design, machining, and finishing.

- Design involves creating a detailed blueprint of the part to be manufactured and then designing the mould around that blueprint

- Machining involves cutting and shaping the mould using precision machinery, such as computer numerical control (CNC) machines

- Finishing involves smoothing and polishing the mould to ensure that it is free of any imperfections or defects

Once the mould tooling process is complete, the mould is used to manufacture parts through a process called injection moulding. Here, molten plastic or metal is injected into the mould, allowing it to cool and harden and then removing the final product from the mould. As you will see in this article, mould tooling is essential to the manufacturing industry as it allows for more efficient and cost-effective production of high-quality parts in large quantities.

8 Ways To Save On Mould Tooling

1. Choosing the Right Surface Finishes

When it comes to mould tooling, a sleek and shiny finish is typically the preferred result. However, achieving this through polishing or shot blasting can add to the overall cost. So, if your mouldings have surfaces that don’t need to be visible, consider opting for a natural finish to reduce costs.

2. Reduce Cycle Times With The Perfect Draft Angle

In the manufacturing sector, time is of the essence and cycle time play a decisive role in determining production costs. To ensure quick ejection of parts from moulds without any damage, an ideal draft angle must be considered. This helps to avoid damage while enabling fast removal which will subsequently reduce overall cycle times.

3. Crafting Multiple Cavities for Greater Functionality

Investing in a multi-cavity tool for producing high volumes of mouldings can be greatly beneficial as the versatility can help reduce the cost per part from the offset. Even though the initial outlay is higher than buying a single cavity tool, it’s more economical to utilise this approach since you’ll get additional parts with each cycle. As a result, you could potentially save a good amount of money compared to purchasing another individual die for mould tooling.

4. Eliminating Undercuts For Easier Ejection

When deciding on a moulding design, it can be tempting to include undercuts for aesthetic or functional purposes. However, they will greatly increase the cost of mould tooling and subsequent maintenance, making them an unwise investment in the long run. To save money upfront when creating your moulds, avoid incorporating any unnecessary undercuts into the design.

5. Consider Volumes and Machining Methods For Mould Tooling

While evaluating the need for side holes in your moulding, it’s important to also factor in volume. If you are producing a relatively small amount of these products, then milling them individually is a more economical choice. However, if the task requires high volumes on an ongoing basis, it’s best to invest in creating a slider during tool design that will save you money over time despite the higher upfront costs.

6. Opt For Heat Treating To Strengthen Tooling

Heat treating can help to improve the strength and durability of your mould tool, allowing for longer lifetimes by hardening its components. Investing in heat treatment before putting your tools into use will cost more upfront, but it could potentially save you money down the line with fewer maintenance requirements.

7. Consider Secondary Processes

If you need a high volume of mouldings, utilising secondary operations such as milling and machining can be more cost-effective than taking the time to build features into the initial tool. However, if your needs are low in quantity, then opting for secondary operations will prove to save money compared to incorporating additional features during the first stage of production.

8. Find the Right Mould Tooling Provider

Investing in the right partner is essential for your success and budget. Expert toolmakers will guide you through a Design for Manufacture (DFM) operation to assist you with saving time and money when it comes to mould tooling. While working with non-UK based toolmaker may appear cheaper at first, this could result in higher shipment costs and you also may not be able to own the tool afterwards.

With the right approach to design for manufacture, mould tooling costs can be greatly reduced while still achieving high-quality results. By implementing these tips and tricks, you’ll be able to save money on your overall production costs while still creating a reliable product that meets your needs. Ultimately, this could prove to be a wise investment that helps drive your business further.

Mould Tooling With PRV Engineering

PRV Engineering was initially established to manufacture Tamper Proof Lid Assemblies for the Metal Packaging Industry. Although we no longer specialise in this type of activity, our team still has the knowledge, expertise and equipment to build and evaluate Simple or Multi Tool Punch and Press Sets. This includes low complexity single level tools up to more intricate progression tooling.

Our team of toolmakers now fabricate Punch, Press and Forming Tools, Die Sets and Tool Spares for customers on a subcontractor level. Additionally, we can improve existing tools with refurbishment services performed on-site or at our facilities. To help minimise any down time that might arise from maintenance or repairs to your tooling system, we also offer pick up and delivery options.

Whether you’re producing a low or high volume of mouldings, PRV Engineering can help. Please contact us for more information or visit the website for a closer look at our range of precision engineering and fabrication services.

Mail:

Mail: