For some reason, many people believe that British manufacturing is dead and claim we no longer make anything. While suggesting that Great Britain transformed the industry is perhaps reaching but we know for a fact that we are still producing many products across various sectors. In this article, we look at the story of British manufacturing with some information from Phil Hamlyn Williams, the author of a new book, How Britain Shaped the Manufacturing World.

Where Did British Manufacturing Begin?

The Industrial Revolution began in the United Kingdom in the late 18th century which contributed to Britain’s early economic prowess. British manufacturing grew tremendously in the 19th century with innovation leading to revolutionary changes in many areas of manufacturing. Some of these include the development of factory systems and the growth of transportation by way of rail and steamships.

During this time, the UK was also leading the way in standardisation and quality control which helped ensure the manufacturing of products at consistently high standards. Britain’s manufacturing dominance began to fade somewhat in the 19th century as other countries, such as the United States and Germany, made headway and caught up. That said, British manufacturing still accounted for a significant amount of global production.

The Steam Age And British Railways

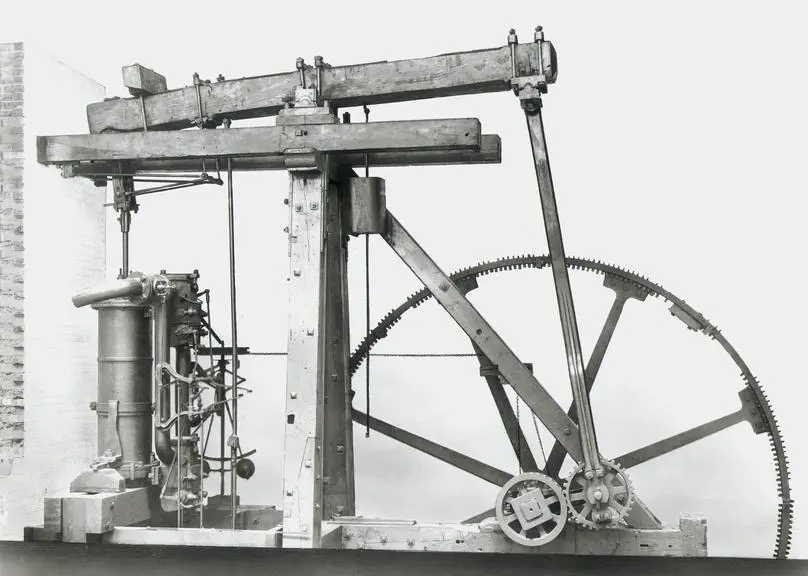

In 17th century Britain, primitive steam engines were used to pump water out of mines but in 1765, Scottish inventor James Watt improved on the design. By increasing the efficiency of steam pumping engines, he added a separate condenser and in 1781, he designed a machine to rotate rather than generate the up-and-down. Further improvements in the 1780s made Watt’s engine a primary source of power in mills, distilleries, canals, and waterworks.

The steam engine’s adoption in industry and as a power source on ships and railway locomotives contributed to the exponential growth of manufacturing capacity and the development of national and international transportation networks during the 19th century.

From Steam Engine To Steam Locomotive

British engineer Richard Trevithick is best known for inventing the steam railway locomotive in 1803. It was an application of the steam engine that James Watt once dismissed as impractical. Trevithick also modified his engine to propel a barge and operate a dredge, turning paddle wheels. Trevithick’s engine, which produced more power than Watt’s by operating at higher pressures, fast became a popular sight in industrial applications in Britain and eventually displaced Watt’s less-efficient design.

The first steam-powered locomotive carrying passengers was the Active, later renamed the Locomotion. Designed by English engineer George Stephenson, its maiden run took place in 1825 but more innovation was to follow. For a new railway line between Liverpool and Manchester, which opened in 1830, Stephenson and his son created the Rocket, which travelled 36 miles (58 kilometres) per hour.

This effectively marked the beginning of Great Britain’s industrial revolution with railways quickly greasing the wheels of trade. Entrepreneurs were eager to invest in railways connecting mines and factories to ports and markets. It didn’t stop there as Thomas Brassey, a renowned railway contractor and civil engineer at the time allegedly constructed one-sixth of Britain’s railways and half of those in France.

British Manufacturing And The Motor Industry

Due to the hazardous consequences of steam-powered vehicles, speed limits were imposed. However, once they were removed, the Daimler factory at Coventry Mills opened its doors for business. Other familiar names in UK manufacturing include Humber, Sunbeam, Morris, Austin and Rolls-Royce among many others. Behind the scenes, Joseph Lucas was working on his manufacturing business, Lucas Industries and nearly created a monopoly in the supply of specific components.

The motor industry also played a significant role in supplying the army and the RAF during WWII. Oil not only powered road vehicles but also ships, aircraft and trains. Considering what transpired during the world wars, it’s easy to see how it created a powerful body of expertise, especially in aviation.

The British government implemented the Shadow Scheme in 1935, a plan created to meet the pressing need for additional aircraft in the buildup to World War II. It would involve using technological transfer from the automotive sector to establish extra capacity. The concept of a jet engine was independently developed by two people, Frank Whittle and Hans von Ohain. Gas turbines, as well as aero engines, were created in response to Whittle’s invention.

The Electrical Age And British Heavy Industry

The transmission of electricity was another source of power with Britain leading the proverbial charge with two Italians (Guglielmo Marconi and Sebastian Ziani de Ferranti) and Germans (Werner von Siemens and Ivan Hirst). They discovered that the British business environment was highly receptive to creative thinking but it did require American investment. This came in the form of Westinghouse with Metropolitan Vickers in Trafford Park, Manchester and General Electric with British Thomson-Houston in Rugby which created a heavy industry.

From there, the three British-managed conglomerates, AEI, English Electric and the British-financed GEC, grew from strength to strength. Together, they brought power to dispersed industry and into the homes of residents. The invention of the telegraph initiated a new industrial revolution in the early years of the 20th century. The Marconi company, which began almost completely with British investors and professionals, introduced radio which proved vital during World War I.

How Two World Wars Impacted British Manufacturing

As we all know too well, war can impact just about everything. The unprovoked Russian invasion of Ukraine is a stark reminder of just how quickly things can escalate. The same can be said for the two world wars which had a major impact on British manufacturing. During the First World War, government regulation and intervention in industry increased, as well as a rise in nationalistic sentiment that resulted in a change in consumer behaviour.

After the conflict, there was an emphasis on mass production and greater efficiency. The Second World War had a more significant impact on British manufacturing as production increased dramatically. Factories had to operate around the clock to meet the increased demand for weapons and other goods. As such, the state gained even more power and control while nationalising certain sectors. After the war, many industries were in decline, and de-industrialisation was on the rise.

When Did British Manufacturing Start Declining?

Following the Second World War, many industries moved to other nations with less expensive labour to benefit from lower manufacturing costs. This was accelerated by the Thatcher administration’s push for deregulation and liberalism, which resulted in greater competition among businesses. While British manufacturing may not be as strong as it once was, there are several industries where the UK still excels, including aerospace and pharmaceuticals. Despite the decline in British manufacturing since the 1970s, the UK is currently the ninth-largest manufacturing country. Overall, the industrial sector in the United Kingdom has grown 1.4% each year since 1948 as stated in a recent ONS report.

What Does Britain Manufacture Today?

As we’ve established, there has been a relative decline in the size of UK manufacturing since the world war but the UK still produces more in absolute terms than before. Now, the UK manufactures a wider range of goods from Nuclear reactors and military equipment to electronics, pharmaceutical products and consumables. Here are some of the products the UK produces today.

- Vehicles including BMW Mini, Nissan, Aston Martin, Rolls Royce, Bentley, Lotus, Morgan and Vauxhall

- Mechanical machinery

- Gas turbines

- Medicines and vaccines

- Computers

- Hard liquor

- Aircraft and aerospace parts

- Running services such as air traffic control and train systems

- Marmite

- Cavendish pianos

- Cadbury’s Dairy Milk

- Henry the Vacuum Cleaner

- Dr Martens shoes

- David Shilling’s Ascot Hats

Now that we’ve highlighted some of the major moments in British manufacturing, what do you think the future holds? Please share your thoughts on our social media using the hashtag #PRVtech. Take a look at the top 5 exports from the UK to global customers.

Mail:

Mail: