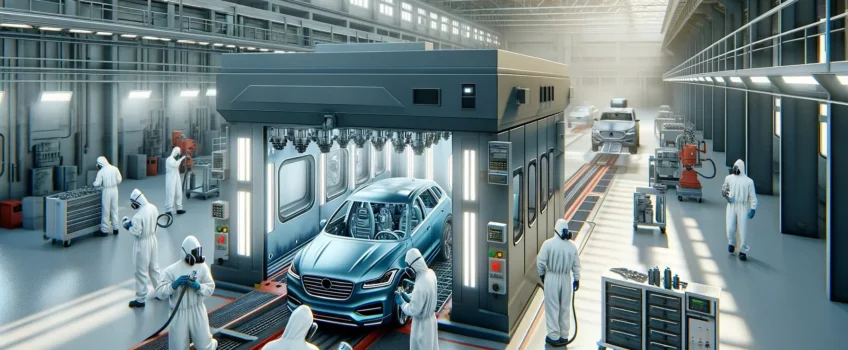

In the intricate machinery of the UK’s engineering sector, Automotive Powder Coating emerges as a vital cog, integral to the industry’s functionality and success. This innovative process has rapidly become a cornerstone in the manufacturing and finishing of automotive components, playing a pivotal role in enhancing both the performance and aesthetics of vehicles.

Pioneering Precision and Durability in Manufacturing

At the heart of Automotive Powder Coating is a dedication to precision and durability. The process involves electrostatically applying a fine powder onto automotive parts, which are then cured under heat to form a skin-like layer. This layer is remarkably resistant to scratches, chips, fading, and corrosion, making it an ideal choice for the harsh conditions encountered by vehicles. It’s not just about making cars look good; it’s about ensuring they last longer, reducing the need for frequent replacements or repairs.

Benefits of Automotive Powder Coating

Automotive Powder Coating stands out as a superior finishing technique, offering a multitude of benefits that significantly enhance the quality and longevity of automotive components. Its growing popularity in the UK’s engineering sector is attributed to several key advantages:

- Enhanced Durability: Powder coatings create a hard finish that is far more resistant to chipping, scratching, and other wear compared to traditional paint. This means longer-lasting protection for vehicles in diverse environments.

- Superior Corrosion Resistance: The coating acts as an effective barrier against rust and corrosion, especially important in the UK’s often wet and salty road conditions.

- Wide Range of Finishes: From glossy to matte and textured, powder coating offers a vast array of finish options, catering to both aesthetic preferences and functional requirements.

- Eco-Friendly Process: Emitting fewer volatile organic compounds (VOCs) than traditional liquid paints, powder coating is a more environmentally friendly choice, aligning with the UK’s sustainability goals.

- Cost-Effective: Despite its higher initial cost, powder coating proves more economical in the long run due to its durability and low maintenance requirements.

- Versatility: Suitable for a wide range of materials and applications, powder coating is not limited to just automotive parts but is also used in aerospace, defence, and other sectors.

- Improved Efficiency: The process is generally faster than traditional painting, with quicker drying times, leading to increased productivity.

Enhancing Aesthetic Appeal with Diverse Colour Options

While the practical benefits are significant, the aesthetic flexibility offered by Automotive Powder Coating cannot be understated. The process opens up a spectrum of colour options and finishes, from glossy and matte to textured. This variety allows for complete customisation, enabling manufacturers and consumers alike to achieve the precise look they desire. It’s a game-changer for car enthusiasts and manufacturers who want their products to stand out in a competitive market, coupled with shot blasting for surface preparation.

In addition to providing an array of colours, powder coating also offers improved durability compared to other painting methods. The powder is cured under heat, resulting in a hard and durable finish that can withstand the rigours of everyday use. This makes it ideal for automotive applications where the vehicles are constantly exposed to various weather conditions and road debris.

Driving Innovation Across Multiple Sectors

The influence of Automotive Powder Coating extends beyond the automotive industry. Its principles of durability, efficiency, and environmental friendliness are being adopted across various sectors in the UK, including aerospace, defence, and even consumer electronics. This cross-industry adoption underscores the versatility and importance of powder coating in modern manufacturing and engineering.

- Aerospace Industry: It’s crucial for aerospace applications because of its lightweight nature and resistance to extreme environmental conditions, such as high temperatures and corrosion, aligning with the industry’s high quality standards.

- Defence Sector: In defence, powder coating’s durability and reliability are key, offering robust finishes for combat vehicles, weaponry, and protective gear, with added corrosion resistance for longevity in harsh environments.

- Consumer Electronics: This technique is significant in consumer electronics for combining aesthetic appeal with functionality, providing a range of finishes and colours for durability in everyday devices like smartphones and laptops.

- Rail Industry: Powder coating is beneficial for both exterior and interior components of trains, resisting weathering and UV rays to maintain appearance, and reducing maintenance needs due to its hard-wearing nature.

- Construction and Architecture: It’s increasingly used in construction for its aesthetic flexibility and durability, applied to structural components and facade elements to protect against the elements and enhance design.

- Oil and Gas Sector: Essential for the oil and gas industry, powder coating withstands extreme conditions like exposure to chemicals and high temperatures, ensuring the safety and longevity of critical equipment.

Conclusion: A Testament to British Engineering Excellence

In conclusion, Automotive Powder Coating is more than just a process; it’s a testament to the innovation and excellence inherent in British engineering. By incorporating this technology, the UK’s engineering sector not only enhances the quality and longevity of its products but also contributes significantly to environmental conservation and aesthetic diversity. As we move forward, Automotive Powder Coating will undoubtedly continue to be a key player in the evolution of UK engineering and manufacturing.

Automotive Powder Coating At PRV Engineering

PRV’s ongoing investment and development programme means that our finishing department is state-of-the-art and all-comprehensive. It consists of a 6 metre Shot Blast room, various Shot Blast cabinets, Powder Coating booth, Wet Paint spray room and a 2.2 metre cubic High Bake Oven. It has allowed us to provide a high quality painted finish to very exacting standards.

As stated by Simon Jones, managing director of PRV Engineering; “As one of the leading engineering services, PRV Engineering can provide you with high quality powder coating services that meet all your requirements. In addition to the application techniques, we have also employed the means to test the finishes for depth and strength.”

If you are looking for a reliable and efficient powder coating service, contact PRV Engineering today. Visit our website for more information and please follow our blog to learn more about engineering, manufacturing and technology.

Mail:

Mail: