Automotive engineering is a hotbed of innovation, and precision machining is the driving force behind its constant evolution. From enhancing performance to improving safety, precision engineering plays a pivotal role in shaping the vehicles we know and love today. As a leading manufacturer in the UK, we specialise in various sectors, including automotive engineering, and in this blog, we will explore the remarkable impact of precision machining in the world of automotive engineering and how it continues to drive advancements while improving quality.

Precision Is Everything In Automotive Engineering

Fuelling Automotive Advancement Precision engineering is at the forefront of pushing the boundaries of what is possible in the automotive industry. By leveraging cutting-edge technologies and advanced manufacturing processes, automotive engineers can unlock new levels of performance, safety, and innovation. Let’s delve into key areas where precision engineering makes a significant impact.

Performance Enhancement

Precision engineering enables automotive manufacturers to optimise the performance of their vehicles. Engine components such as pistons, crankshafts, and camshafts undergo meticulous design and manufacturing processes to ensure efficient power delivery, reduced friction, and improved fuel economy. Advanced materials and computer-aided design (CAD) allow engineers to fine-tune every aspect of the engine, resulting in higher horsepower, smoother acceleration, and an overall exhilarating driving experience.

Safety and Reliability

Precision engineering plays a vital role in ensuring the safety and reliability of vehicles. Components like braking systems, suspension systems, and chassis structures undergo rigorous engineering and manufacturing processes to withstand immense forces and provide optimal stability and control. By employing advanced manufacturing techniques such as computer numerical control (CNC) machining and 3D printing, automotive engineers can create intricate and high-strength parts that meet the stringent safety standards of the industry.

Lightweight Design

In an era where environmental concerns take centre stage, automotive engineers strive to reduce vehicle weight while maintaining structural integrity. Precision engineering allows for the development of lightweight materials such as high-strength alloys and composites, which not only enhance fuel efficiency but also improve handling and overall performance. Advanced fabrication techniques, including laser cutting and hydroforming, enable the creation of complex lightweight structures with utmost precision, striking a balance between weight reduction and safety.

Applications Of Precision Machining In Automotive Engineering

Precision machining is a crucial aspect of automotive engineering as it enables the creation of intricate and high-quality components. By leveraging advanced machining techniques and state-of-the-art equipment, automotive engineers achieve unparalleled precision, accuracy, and repeatability in the manufacturing process. Here’s how precision machining is utilised in automotive engineering:

Engine Components

Precision machining plays a crucial role in manufacturing engine components such as cylinder blocks, cylinder heads, crankshafts, and pistons. Computer numerical control (CNC) machining allows for precise shaping and finishing, resulting in improved power output, reduced friction, and enhanced durability.

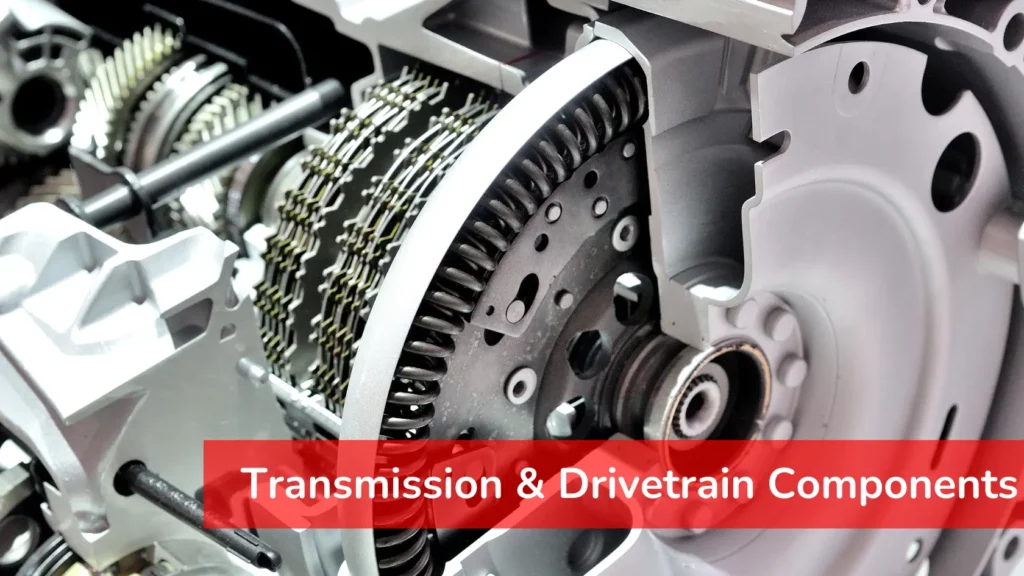

Transmission and Drivetrain

Precision machining is essential in the production of transmission and drivetrain components. Gears, shafts, bearings, and differential housings undergo meticulous machining to ensure accurate tooth profiles, smooth operation, and minimal power loss. Advanced machining processes such as gear hobbing and grinding enable the creation of precisely meshing gear systems.

Suspension and Steering Systems

Precision machining is vital in manufacturing suspension and steering components. Control arms, steering knuckles, and tie rods require precise machining to achieve dimensional tolerances and fitment. CNC machining ensures accurate shaping and drilling, leading to improved handling dynamics and a better overall driving experience.

Brake Systems

Precision machining plays a critical role in manufacturing brake components. Brake callipers, discs, and pistons undergo precision machining to achieve dimensional accuracy and surface finish. CNC milling and turning operations enable the creation of intricate brake calliper designs and precise brake disc profiles, ensuring efficient heat dissipation and consistent braking performance.

Fuel Injection Systems

Precision machining is fundamental in producing fuel injection system components. Fuel injectors, fuel rails, and throttle bodies require precise machining for accurate flow rates, tight sealing, and precise fuel atomisation. Advanced machining techniques achieve the necessary injector spray patterns, maximising engine performance.

Custom Components and Prototyping in Automotive Engineering

Precision machining is invaluable for creating custom components and prototypes in automotive engineering. Unique engine parts, specialised brackets, and one-off performance components can be designed and manufactured with precision machining techniques. Prototyping using CNC machining allows engineers to validate designs, test functionality, and refine concepts before full-scale production.

Also Read: Building Safer, Lighter Vehicles Using Composite Materials

Frequently Asked Questions about Automotive Engineering

How does precision engineering contribute to fuel efficiency in vehicles?

Precision engineering enables the design and production of high-performance engine components, which improve fuel efficiency. Reduced friction, optimised combustion, and fine-tuned engine parameters maximise energy conversion, resulting in better mileage and reduced carbon emissions.

What role does precision engineering play in electric vehicles (EVs)?

Precision engineering is crucial in the development of electric vehicles. It involves the design and manufacturing of lightweight yet robust battery packs, electric motors, and power electronics. Precise machining and assembly techniques create efficient electric drivetrains that maximise range and enhance overall vehicle performance.

How does precision engineering impact automotive safety?

Precision-engineered components, such as advanced braking systems and structural reinforcements, ensure automotive safety. Meticulous machining techniques and materials with exceptional strength-to-weight ratios create robust safety systems that protect occupants during collisions and provide enhanced stability and control.

Conclusion: Automotive Engineering

Precision engineering and machining have revolutionised the automotive industry, driving advancements in performance, safety, and innovation. Through cutting-edge technologies and meticulous manufacturing processes, automotive engineers can push the boundaries of what is possible in vehicle design and production.

At PRV Engineering, our large facility in Pontypool includes a CNC machining and sheet metal fabrication centre serving a multitude of industries. This includes automotive manufacturing, defence, aerospace, construction and rail among others. Contact us if you have a project in mind or would like more information on the services we provide.

For more articles covering all the latest updates in engineering, manufacturing and technology, please follow our blogs and follow us on social media.

Mail:

Mail: